The growing importance of viral vectors

Viral vectors have become indispensable tools in advanced therapeutics for a range of challenging medical conditions, including monogenetic diseases and cancers. For example, adeno-associated virus (AAV) vectors are utilized in treating genetic disorders, while Lentivirus vectors find applications in ex vivo cellular therapies like CAR-T cell, or bone marrow, Oncolytic Adenoviruses, and Vesicular stomatitis virus (VSV) vectors are employed in cancer therapies.

Addressing viral vector production shortages

Hundreds of new clinical trials have been initiated in the past several years, reflecting the growing importance of these vectors. However, despite these promising advancements, the production of viral vectors has experienced significant bottlenecks in clinical trials using viral vector platforms.

This concern has been discussed in forums such as the FDA’s Center for Biologics Evaluation and Research (CBER), and the American Society of Gene and Cell Therapy. The importance of bioproduction was emphasized in an Executive Order on Advancing Biotechnology and Biomanufacturing Innovation for a Sustainable, Safe, and Secure American Bioeconomy by the US President.

The shortage of virus production capacity is apparent and continues to be the major obstacle to delivering advanced treatment to patients.

The importance of establishing a cGMP virus vector production facility in Minnesota

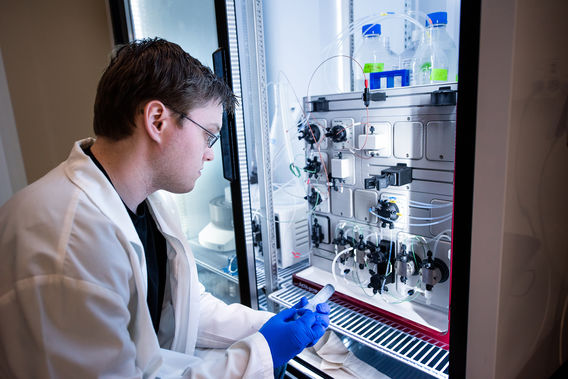

The Hormel Institute and the University of Minnesota are committed to bringing scientific advance-ments back to patients in Minnesota. However, the lack of an in-house vector production capability poses a challenge to accomplishing this important mission.

Similar facilities in other academic institutions (e.g., University of Pennsylvania, University of North Carolina, and Washington State University) or healthcare institutions (Nationwide Children’s Hospital in Ohio, etc.) prioritize internal projects to boost NIH grant funding, clinical trial implementation, and to advance commercialization of the therapeutics.

Having a cGMP Virus Vector Production Facility at the University of Minnesota is essential. Such a facility would not only enhance scientific research but also foster its clinical translation, aligning with one of the University of Minnesota’s core missions.

Production of high-demand viruses for research must be prioritized

At present, all vector platforms (AAV, Ad, LV, etc) are in high demand, and there are many other recombinant viruses that can undoubtedly be employed in the future. Investing in the production of these high-demand viruses for academic and industrial purposes stands as a logical and economically viable decision.

Geographical location is not the primary concern, as cGMP production is primarily a stand-alone process. The important factors in decision-making involve the capacity of existing buildings and their current biosafety compatibility (BSL2), as these factors influence remodeling costs. Utilizing an already BSL2-compatible building will significantly reduce costs compared to a new construction.

Location considerations: Proximity to healthcare providers and local workforce experience

Potential locations include the St. Paul campus and The Hormel Institute in Austin, Minnesota, benefiting from the proximity to major healthcare providers in the Twin Cities and Rochester, Minnesota. Apart from the scientific benefits, cGMP production necessitates a skilled and reliable workforce at various levels of education and experience.

The University of Minnesota and The Hormel Institute are well equipped to provide training, super-vision, and administration of viral vector scale-up production, as well as QA/QC to ensure the safety, consistency, and quality of vectors as mandated by the FDA. In this regard, the project holds the potential to create 10-15 sustainable, well-paid jobs on-site, offering a significant boost to the local economy, particularly for the City of Austin.

Key goals

Establishing a cGMP viral vector production facility for clinical-grade viruses will greatly expedite the University of Minnesota’s research journey toward applying vector-based therapies in clinical settings. This initiative aims to ensure that novel, cutting-edge technology is readily accessible to patients. Ultimately, the long-term goal of establishing production facilities is to fortify the University of Minnesota’s position as a national and international leader in pioneering novel biological treatments.